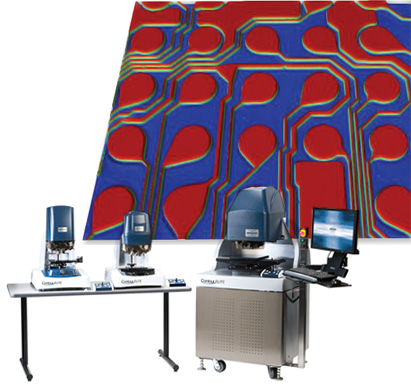

Bruker Contour Elite X

3D Optical Profiler for Surface Metrology

Bruker Contour Elite X is a 3D optical microscope for production-ready metrology and high-fidelity imaging for industrial applications.

The Contour Elite X is designed for a wide range of demanding production metrology applications in R&D, quality assurance and process quality control.

- Unmatched measurement capabilities

- Quantitative, repeatable surface data for R&D.

- Highest vertical resolution over the industry’s largest field of view.

- User-friendly

- Easy-to-use characterisation and analysis software.

- Flexible staging and fixtures for various applications.

- High-fidelity imaging

- Colour and monochrome imaging, revealing previously hidden microscopic details.

- True colour imaging, colour segmentation and metrology.

- Fast and productive

- Rapid imaging.

- Full automated and production-ready.

Contact us for more information and quotes:

+44 (0)1223 422 269 or info@blue-scientific.com

Download the brochure Contact us

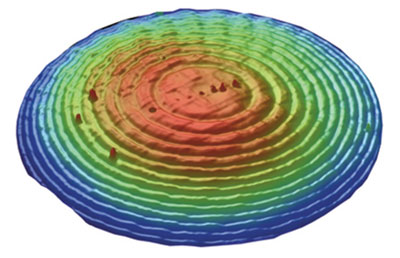

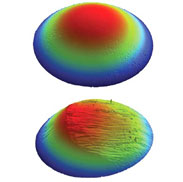

Stitched 3D optical microscope measurement of a contact lens

Applications

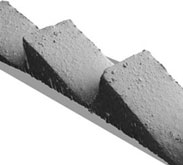

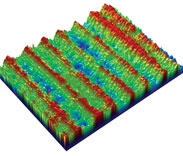

Precision Machining and Tooling

Determine surface finish, critical angles, spacing, radii and other dimensions. Contour Elite 3D optical microscopes ensure high vibration tolerance and measurement repeatability, even in manufacturing environments with tight production specification limits.

A large field of view and objective magnifications from 1X to 115X enable characterisation of a wide range of surface shapes and textures. Optional high-resolution colour or monochrome imaging reveals surface details that otherwise would be difficult or even impossible to see. Rapidly select areas of interest and collect critical metrology data from specific regions.

Left: 3D optical image of saw blade teeth

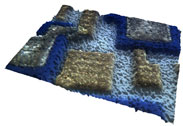

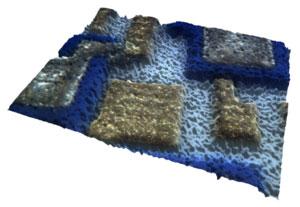

Semiconductors and MEMS

With high speed and accuracy, Contour Elite 3D optical microscopes are ideal for QC/process monitoring. They also have the sensitivity and stability necessary for precision 3D surface measurements in applications that are challenging for other metrology instruments, such as advanced QA/QC and R&D applications in the high-brightness LED, solar, semiconductor and MEMS markets. Critical metrology includes measuring film thickness, layer and substrate roughness, and monitoring and validating dimensional parameters such as RA roughness, pitch, width and height.

Contour Elite microscopes offer the best combined lateral and vertical resolution and the industry’s largest field of view, with a sub-nanometer to >10mm vertical range. High-fidelity imaging reveals minute surface details that would otherwise be difficult or impossible to see. Data segmentation based on color or grayscale information enables users to rapidly select areas of interest and collect critical metrology data from specific regions. See the sample along with its true 3D topography, for better problem-solving in engineered surface applications.

Left: 3D height map of a printed circuit board (PCB) with colour image overlay.

Medical Devices and Implants

Contour Elite 3D optical microscopes can be used to screen for defects (eg scratches and pits) in orthopedica implants and other medical devices. You can define lateral and vertical thresholds, with automatic part rejection and reason logging for optimised process control.

Even drug coatings can be measured for roughness and thickness, in addition to the material inside the coating. Samples can be various shapes and sizes and different material types, to cover a variety of medical devices and implants. The dynamic range is large for measuring very rough to extremely smooth surfaces.

Acquire data-rich, 3D images with superior resolution and repeatability, to gain greater insight into part performance and functionality.

Left: Hip implant surface before and after wear testing

Automotive and Aerospace

Understanding surface wear and its underlying causes is critical to the manufacture and maintenance of automotive and aerospace parts, such as bearings, seals, drive trains, shafts and brake components. The advanced surface metrology and imaging capabilities of Contour Elite X 3D optical microscope helps engineers understand wear and correlate it with particular manufacturing processes and wear mechanisms.

Contour Elite X combines multiple measurements into a larger dataset, to characterise areas more accurately and in greater detail. This highlights data trends such as waviness, lay or a predominance of ridges or scratches.

Shafts, mating or connecting surfaces, and close-tolerance or irregularly-shaped parts are often challenging to measure. Contour Elite X is able to measure difficult areas such as shaft interiors, quantitatively and repeatably. Custom investigation of surface data provides thousands of different analysis parameters. High-fidelity greyscale and colour imaging, combined with Bruker’s side illumination and advanced algorithms, allows users to collect accurate metrology data with corresponding surface images for complete surface characterisation.

Left: 3D surface analysis of a brake rotor.

Accurate Metrology and High-Fidelity Imaging

Contour Elite X delivers the best available lateral resolution in an industrial 3D optical microscope, for quantifying edge variations on even the smallest structures. With high-fidelity imaging, surface details are revealed that would otherwise be difficult or even impossible to see. Data can be segmented into colour and greyscale information to select areas of interest and collect critical metrology data from specified regions.

Robust and Reliable

The Contour Elite X has a proprietary internal laser reference and custom-designed industrial cabinet for optimum stability and robustness. The system is equipped for almost any production environment:

- Air table stabiliser kit for enhanced X, Y, Z wafer placement.

- PDU PDU, EMO and vacuum systems optimised for integration.

- Modified vacuum chucks, compatible with autoloader end-effectors.

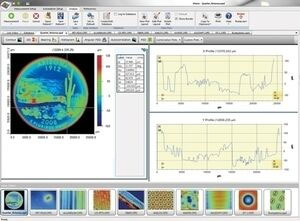

Intuitive Software

The Contour Elite X uses Bruker’s award-winning Vision64 software for production operators:

- Intuitive access to easy-to-use tools

- Customise process workflows

- Automated mapping

- Measurement recipes

Vision64 includes pre-programmed filters and analyses for:

- LEDs

- Solar cells

- Thick films

- Semiconductors

- Ophthalmic and medical devices

- Precision machining

- MEMS

- Tribology

Fully Automated for Precision

The Contour Elite X’s motorised stage provides 12″ encoded movement in the X and Y directions. Sample positioning is made easy with the joystick and software controls. Various automated routines are available, including multi-point data collection and stitching for large-area analyses. The system’s 0.5 micron encoders ensure reliable, repeatable automation and sample positioning.

Recorded Webinars