New Bruker TriboLab CMP for Small-Scale Wafer Polishing Characterisation

The Bruker TriboLab CMP is a new system for small-scale Chemical Mechanical Wafer Polishing in R&D. It reproduces full-scale wafer polishing process conditions with unique characterisation features. This is a new, updated system replacing the previous CP-4.

Blue Scientific is the official Nordic distributor for Bruker Nano surface analysis instruments. For more information please get in touch:

Bruker Nano Surface analysis instruments

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

TriboLab CMP

The TriboLab CMP Process and Material Characterisation system provides unique characterisation capabilities, for developing chemical mechanical polishing (CMP) processes. The system is based on Bruker’s established UMT TriboLab™ mechanical testing platform.

Unique Capabilities

The TriboLab CMP is the only system available with all these features, for the accurate and complete characterisation of CMP processes and consumables:

- A broad range of polishing pressures (0.05-50 psi)

- Range of speeds (1 to 500 rpm)

- Friction

- Acoustic emissions

- Surface temperature measurements

Detailed Data from Small-Scale Tests

The TriboLab CMP system delivers highly accurate and repeatable measurements. These are valuable throughout the CMP process, for qualification, inspection and ongoing functionality testing.

By performing tests on small coupons rather than full-scale whole-wafer measurements, you can reduce costs substantially.

Data is collected throughout the entire test from the moment the substrate touches the pad. Make early-stage process development decisions with complete, detailed data.

On-board diagnostics are provided as standard. Understand your polishing processes more clearly, with enhanced visibility into transient polishing properties.

Further Information

Blue Scientific is the official Nordic distributor of the TriboLab CMP. For more information, or if you have any questions, please get in touch:

Bruker TriboLab CMP

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

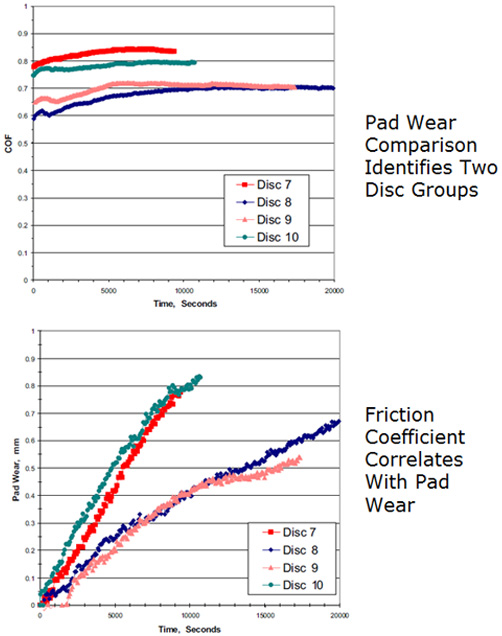

Testing Conditioning Discs on CMP Tester. Tests identify two groups of discs. Friction coefficient tests correlate with pad wear.