Bruker Hysitron PI 95

In-situ depth-sensing nanomechanical test system for TEM

The Hysitron PI 95 is the first full-fledged depth-sensing indenter for nanomechanical testing inside Transmission Electron Microscopes (TEM). Acquire quantitative mechanical data while simultaneously imaging the mechanical response of nanoscale materials in real time. Data is synchronised with the video, to help you understand the causes of force or displacement transients, including dislocation bursts, phase transformations, spalling, shear banding and fractures.

- Quantitative nanomechanical testing

- Compatible with most major TEMs inc JEOL, FEI (Philips), Hitachi & Zeiss (LEO)

- Advanced performech digital controller with 78kHz feedback rate

- Active vibration dampening, with Hysitron’s proprietary Q-Control

- Upgrade options including heating, electrical, nanoScratch and dynamic

Contact us for more information and quotes:

+44 (0)1223 422 269 or info@blue-scientific.com

Testing Modes

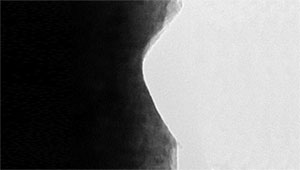

Nanoindentation

- Apply localised stress to electron transparent samples

- Observe deformation mechanisms and micro-structural changes

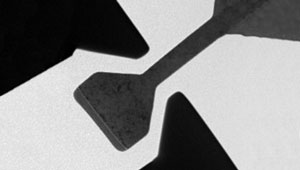

Tensile

- Measure tensile properties of nanostructures

- Use the transducer’s reverse actuation capabilities

- Push-to-Pull (PTP) sample mounts

Bending

- Bend cantilevers or nanobeams

- Create fractures and observe the extent of damage

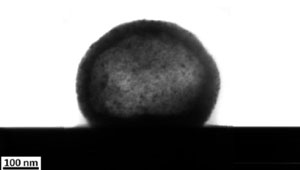

Compression

- Study size-dependent mechanical properties

- Measure nanoscale pillars and particles

- Simultaneous TEM observation

Optional Upgrade Modes

- Heating up to 800°C

- Electrical characterisation

- Push-to-pull device

- nanDynamic mode

- nanoScratch mode