New Bruker Contour CMM – Optical Coordinate Measurement

New Bruker CMM – Optical Coordinate Measurement Machine (CMM)

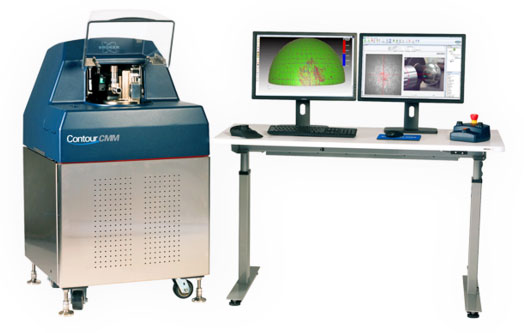

The new Contour CMM from Bruker is the world’s first optical coordinate measurement machine that provides information about surface roughness, shape and size from just one measurement.

The Contour CMM has been tailored for applications that require both precise dimensional metrology and 3D surface analysis. With just one instrument, you can simultaneously measure:

- Nanoscale height

- Surface texture

- 3D coordinates for geometric dimensioning and tolerancing (GD&T)

Blue Scientific is the exclusive distributor for Bruker Nano in the Nordic region (Sweden, Denmark, Finland and Norway). If you have any questions, please get in touch:

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

More about Bruker Nano instruments

[hr]

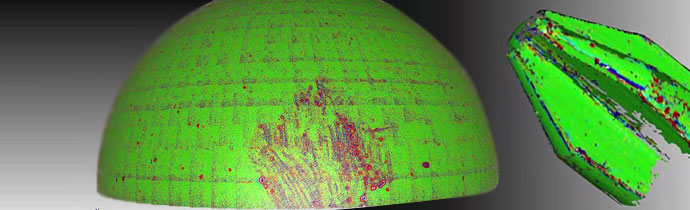

Measuring a standard 10mm diameter sphere using the Bruker Contour CMM. The high density point cloud is enlarged and displayed on the right.

Non-Contact, High Density 3D Data

- Ultimate Surface Resolution – Developed based on decades of experience interferometric metrology technology. The white light interferometry (WLI) system uses Bruker’s proprietary optical profiling technology.

- 3D Optical Profiler and CMM – Extremely high vertical and lateral resolution. Take non-contact nanoscale surface roughness measurements at known locations in geometric space, using highly accurate stages.

- Metrology Data Continuum – For industry standard surface roughness measurements, with geometric dimensioning and tolerance (GD&T) analysis.

3D Surface Texture and Roughness

Using a proprietary 3D surface roughness display method, visualise the surface texture map in true three-dimensional space.

Geometric Dimensional Analysis

- True 3D Data and Analysis – Point clouds are captured, using interferometric surface data. These data points are then displayed in 3D geometric space.

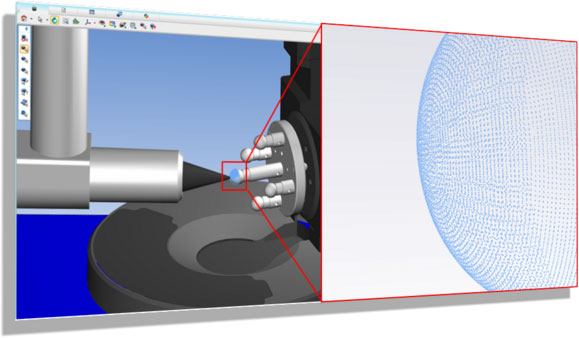

- Capture Geometric Form and Shape – The software contains a Dimensional Metrology Interface Standard module (VisionDMIS), for controlling the precision 5-axis staging system and to collect the positional data of surface measurements.

- Form and Shape Analysis – Perform standard 3D form, shape and size analyses, for CAD comparisons and inspection reports.

Applications

Precision Machined Parts

Measure the geometric features of small, precision-machined parts. Rapidly and accurately measure the critical dimensions of lines, angles, etc.

The software (VisionDMIS) creates a part-coordinate system from high-density and accuracy surface measurements. This can be used for standard GD&T analysis.

Orthopedic Implants and Medical Parts

Using interferometric surface data, point clouds are captured and displayed in 3D to produce a true part-coordinate system. These can be analysed with the VisionDMIS module for traditional GD&T analysis.

Analyse the critical dimensions of 3D parts, along with the surface roughness parameters of selected areas.

Blue Scientific is the exclusive distributor for Bruker Nano Surface Analysis in Scandinavia (Sweden, Denmark, Finland and Norway). For more information and quotes, please get in touch: