Determine Food Shelf Life with TD-NMR

Measuring oil and moisture content is a vital part of process and quality control in the food industry. TD-NMR (Time Domain NMR) is a fast, reliable and cost-effective method, which is easy to use and implement into a production line.

Contact us on 01223 422 269 or info@blue-scientific.com

[hr]Food Shelf Life and Moisture Content

There are a number of reasons why it is important to measure the moisture content of food products:

- Product quality – Water content affects the texture, taste, appearance and stability of foods.

- Spoilage – Moisture allows micro-organisms to grow, so certain foods must be dried below specific moisture levels to minimise spoilage.

- Process control – Measuring the moisture content during processing and packaging is important to maximise shelf life, and ensure the consistent quality of end products.

- Labelling and legal requirements – Comply with legal requirements regarding the maximum and minimum amount of water present in certain types of food.

- Detect fraud – The cost of raw materials is often based on weight. Detect the addition of water to raw materials and ensure you’re paying for quality products.

TD-NMR

TD-NMR is a variant of NMR, an advanced scientific method for analysing molecules. Bruker minispec TD-NMR analysers are designed for specific applications, making the technology accessible for all operators, in real-world applications.

TD-NMR is ideal for measuring the moisture content of a sample, and is widely used in the food industry. Other analytical techniques struggle to measure water content accurately, because water molecules can exist in different molecular environments, with different physicochemical properties. TD-NMR can measure water in different molecular environments, and distinguish water from other molecular components in food.

Measuring Oil and Moisture in Snack Foods

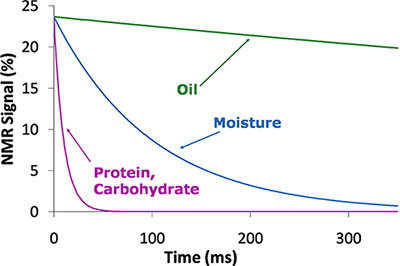

This example describes how to measure oil and moisture content in snack foods using TD-NMR. Oil, moisture, protein and carbohydrates have different relaxation properties, making it possible to distinguish and quantify them.

TD-NMR relaxation profiles for oil, moisture, protein and carbohydrates

The moisture and oil content of the sample are measured using a spin-echo pulse method. The difference in intensity of the FID and the echo correlates with the moisture content. The echo intensity correlates with the oil content.

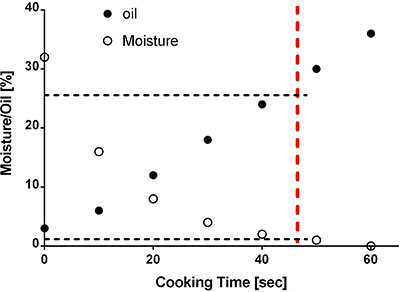

Knowing the moisture and oil content enables the cooking time to be optimised. In this example, the food is cooked when the moisture is less than 1.5% and the oil content should not exceed 25-35%. Using this data, cooking time can be adjusted when oil and moisture content varies, for perfect results every time.

Using the oil and moisture content to determine the optimum cooking time

Fast Analysis

TD-NMR determines moisture content within 30 seconds for a 15 – 20g sample. In comparison, Karl-Fischer titration takes 30 – 60 minutes for a 0.5g sample, and oven drying takes several hours. The Bruker minispec guides you through the process quickly, maximising production and reducing defective product and waste.

Food Shelf Life

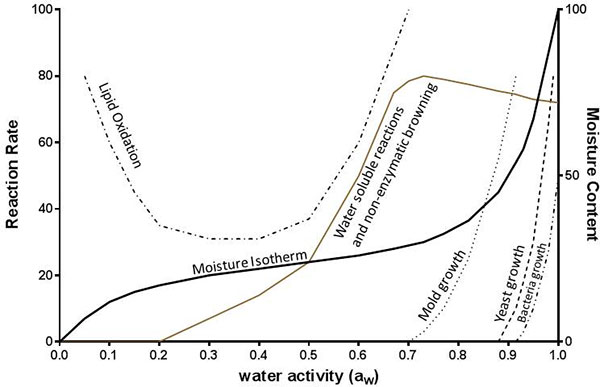

Shelf life is typically determined using human sensory testing for appearance and taste, and by measuring fat oxidation, texture and moisture content. “End of Shelf Life” (EoSL) parameters for fried snack foods are moisture and texture. Another critical factor for shelf-life determination is water activity (aw) which can be reduced with solutes, freezing, drying and packaging.

Parameters affecting food shelf life

The texture of dried snack foods depends on moisture content. For example, if the moisture level of potato crisps increases above 2.5%, the crisps become chewy and develop a stale taste.

The shelf life of snack food is also highly influenced by the permeability of the packaging material. Measuring moisture content is also a way of analysing packaging-dependent shelf life. TD-NMR can even measure food through packaging (40 or 50 mm diameter probe set-up). Accelerated shelf life studies can be carried out at temperatures from -100˚C to +200˚C, using a variable temperature probe.

TD-NMR throughout the Production Process

TD-NMR can be used at each stage of the food production process:

- Dry ingredients

- Fat/moisture content

- Dough making

- Moisture binding

- Effect of mixing parameters

- Check finished dough

- Effect of freezing

- Frying/baking/drying

- Fat/moisture content

- Process monitoring

- Monitoring product quality

- Drying kinetics

- Final product

- Fat/moisture content

- In-package testing

-

- Fat/moisture content

-

Bruker minispec TD-NMR

The Bruker minispec is a benchtop TD-NMR analyser, which comes calibrated for specific applications, including food product control. It is fast, reliable and easy to use, even by untrained personnel. All sample types can be analysed, including liquids and powders, and foods can be analysed in their packaging. The NMR results are generated from all hydrogen nuclei in the entire sample volume, and are not affected by surface, colour, salt or spice content.

Blue Scientific is the exclusive distributor for Bruker TD-NMR in the UK and Ireland, and we are available to discuss your application and answer your questions. For more information and demonstrations, contact us:

Contact us on 01223 422 269 or info@blue-scientific.com