IMS 7f-Auto

Fully automated vertical SIMS (Secondary Ion Mass Spectrometer)

The CAMECA IMS 7f-Auto is a SIMS system for high precision elemental and isotopic analysis in device development and process control.

Powerful analytical features

- Unparalleled depth profiling capabilities with high depth resolution and high dynamic range.

- High transmission mass spectrometer and two reactive, high-density ion sources (O2+ and Cs+)

- High sputter rate and excellent detection limits.

- Direct ion microscopy and scanning microprobe imaging.

Automation and efficiency

- Redesigned, in-line primary column for fast, easy primary beam tuning and current stability.

- Automated routines.

- Motorised storage chamber with automated sample changing.

- Analyse multiple samples in chained or remote mode.

- 24 hour operation with minimal intervention

High reproducibility

- RSD < 0.5 % reproducibility

- Excellent detection limits

Contact us for more information and quotes:

+44 (0)1223 422 269 or info@blue-scientific.com

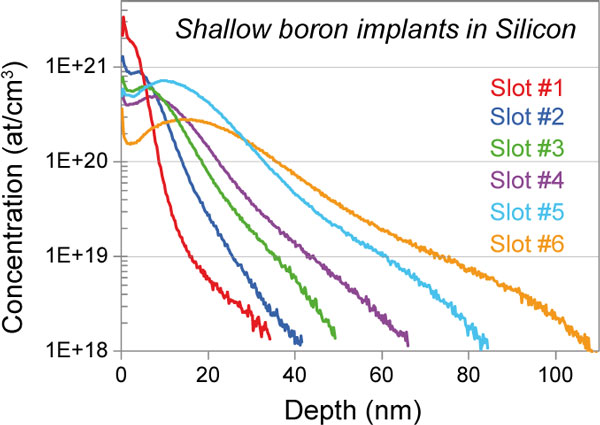

Depth profile of boron implants in silicon

SIMS is a versatile technique for a wide range of applications. If your area of interest isn’t mentioned here, or if you’d like more information about any of these areas, please get in touch.

Battery and fuel cell development

Researchers at Tohoku University used SIMS to precisely measure the lithium diffusion coefficient in cathode materials, obtaining more stable results than alternative methods. More details…

Detect trapped hydrogen in aluminum alloy

Dynamic SIMS is one of the most promising techniques for visualising the local distribution of H atoms in metallic materials and hydrogen embrittlement studies.

Oxygen depth profiling in Zn coated steel

The IMS 7f-Auto’s unique depth profiling and ion imaging capabilities are useful in studies of inclusions and segregation effects in alloys.

Small area analysis in Sn-Cu wire structures

Due to its outstanding imaging capabilities, the IMS 7f-Auto is ideal for advanced engineering materials R&D, such as diffusion in polycrystalline samples and surface imaging analysis.

Implant depth profiling

The IMS 7f-Auto is widely used for dopant monitoring in the semiconductor industry, for various species and material systems.

Impurity control

Dynamic SIMS is one of the most efficient techniques for measuring trace concentrations of impurities in semiconductors.

Dopant monitoring in LED devices

Investigate the composition and characterise the elemental distribution of dopants and impurities on various layers, in R&D and process control.

Materials for energy and catalysis

SIMS nitrogen concentration depth profiles in Cuprous oxide (Cu2O) films doped with nitrogen plasma help enhancing the conductivity of this material used for low-cost solar-energy conversion and photocatalysis.

CIGS thin film solar cells

Dynamic SIMS instruments are best fit to characterize the elemental in-depth distribution (matrix species & alkali metals Na and K) in various different CIGS thin films.

Purity control in PV Si feedstock

The IMS 7f-Auto is the tool of choice for quality control of the Si purification process which is mandatory to ensure high yield manufacturing of Si-based solar cell devices.

Nuclear glass alteration mechanisms

Offering excellent depth profiling capabilities for low concentration elements and high precision isotopic analyses, the IMS 7f-Auto is a powerful tool for analyzing nuclear glasses.

Helium migration in nuclear reactors

SIMS offers better sensitivity, dynamic range and depth resolution than other techniques used to analyse nuclear materials.

These application notes are available to download from CAMECA:

- Auto Light Elements

- Materials Analysis in Nuclear Science

- SIMS Applications in Nuclear Science: Fission Products Behavior

- LEDs

Watch these on-demand webinars from CAMECA (registration required).

Dynamic SIMS for Characterisation of Nuclear Materials (32 mins)

To guarantee the longevity of structural nuclear materials and learn about the mechanisms occuring during reactor accidents, it’s important to understand the diffusion and migration mechanisms of fission products in nuclear materials and fuel.

Various materials can be analysed with SIMS after ion implantation with natural isotopes of high fission yield species (eg molybdenum, helium, xenon, iodine). The webinar also covers dynamic SIMS characterisation of nuclear particles from nuclear facilities for safeguarding purposes.

The data presented in this webinar is a collaborations between CAMECA and several users from the nuclear science field worldwide.

Optimising Detection Limits for Light Elements (H, C, O) (25 mins)

This webinar focuses on optimising detection limits for light elements (hydrogen, carbon and oxygen atmospheric species) in silicon-based materials using dynamic SIMS.

Data about H, C and O low-level impurities introduced during processing and/or ageing is important for understanding semiconductor device lifetime and failure. Dynamic SIMS is useful for evaluating the concentration of impurities in solids, because of its high sensitivity and depth profiling capabilities.

The webinar explains how detection limits can be improved using a pre-sputtering method. Results include data acquired using multiple sample holders and an automated storage chamber.