What is Dynamic SIMS?

SIMS (Secondary Ion Mass Spectrometry) is the most sensitive elemental and isotopic surface microanalysis technique. Dynamic SIMS mode enables you to analyse bulk composition and in-depth distribution of trace elements. Here’s an overview of how it works, and what it can be used for.

Blue Scientific is the official distributor for CAMECA in the UK, Ireland and Finland. For more information or quotes, please get in touch.

SIMS instruments

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Follow @blue_scientificSIMS vs Dynamic SIMS

SIMS (Secondary Ion Mass Spectrometry) is the most sensitive elemental and isotopic surface microanalysis technique:

- Extremely high sensitivity to all elements from Hydrogen to Uranium and above

- Detection limit down to ppb level for many elements

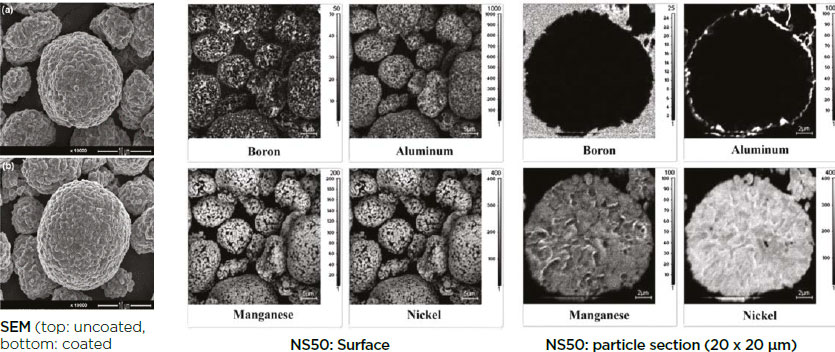

- High lateral resolution imaging down to 40 nm

- Very low background for high dynamic range (>5 decades)

Static SIMS focuses solely on the first top monolayer, mostly for molecular characterization.

Dynamic SIMS mode investigates bulk composition and in-depth distribution of trace elements, with a depth resolution from sub-nm to tens of nm.

All CAMECA SIMS instruments are capable of dynamic SIMS.

How Static SIMS Works

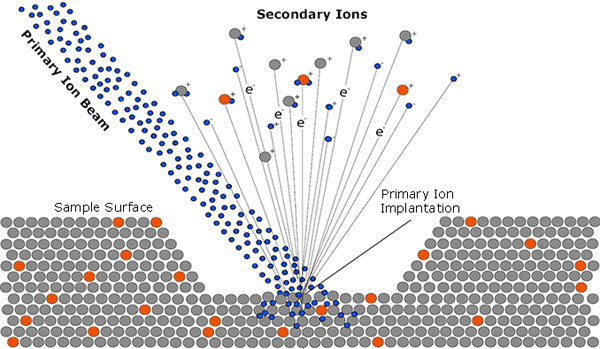

A solid sample is sputtered by primary ions of energy (just a few keV ). Particles are emmited, a fraction of which are ionised. The secondary ion emission is measured with a mass spectrometer.

This provides information about the elemental, isotopic and molecular composition of atomic layers at the surface.

Secondary ion yields vary greatly according to the chemical environment and sputtering conditions eg ion, energy, angle. This adds complexity to the quantitative aspect of the technique. SIMS is known as the most sensitive elemental and isotopic surface analysis technique.

Which Materials can you Analyse?

SIMS can be used to analyse any type of solid material that can be kept under vacuum, including insulators, semiconductors and metals. It’s a destructive technique, because it involves sputtering.

Dynamic SIMS Mode

While static SIMS measures only the first top monolayer, dynamic SIMS measures bulk composition and in-depth distribution of trace elements to a depth resolution of sub-nm to tens of nm.

Dynamic SIMS instruments have oxygen and cesium primary ion beams. This enhances the positive or negative secondary ion intensity.

The process starts from the surface (or through an interface). By increasing the primary ion dose implanted in the target, the primary species concentration (oxygen or cesium) will reach an equilibrium. This depends on the sputtering conditions and the nature of the target. The equilibirum corresponds to a sputtering steady state. Once it’s reached, reliable quantification is possible with reference standard samples, using Relative Sensitivity Factors.

From a paper by Tae Eun Hong et al. J Appl, Electrochem (2012).

Applications

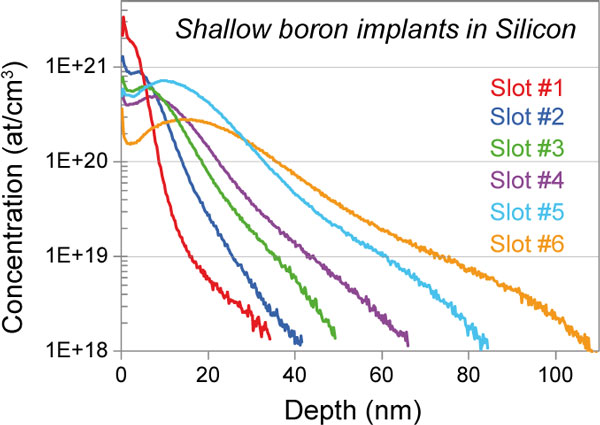

Dynamic SIMS is often used to measure the in-depth distribution of trace elements eg dopants or contaminants in semiconductors. Various depths and depth resolutions can be investigated by adjusting the ion impact energy:

- Low energy (down to 150eV) is used to reduce atomic mixing caused by collision cascades and for depth resolution down to sub-nano-metre level.

- High energy (up to 20 keV) is used for deeper analysis (tens of microns), faster sputter rates (µm per min range) and lower detection limits.

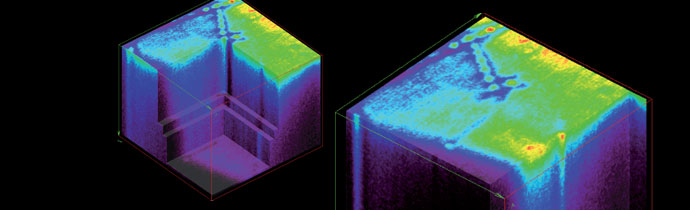

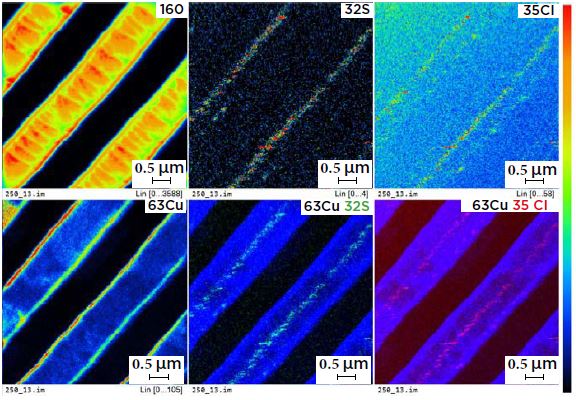

Dynamic SIMS is also used for high resolution imaging analyses and high precision isotope ratio measurements.

On-Demand Webinar

Find out more about dynamic SIMS in this on-demand webinar from CAMECA. The 20 minute presentation provides an introduction to the technique:

- Primary and secondary beam species

- Relative sensitivity for various elements

- Matrix effects

- Depth and lateral resolution

- Depth profiling (choosing impact energy, sputtering rate and calibration methods)

- Scanning ion imaging mode

- Dynamic SIMS’ key analytical characteristics

It’s presented by Dr Paula Peres, SIMS Product Manager at CAMECA. The recorded webinar is available to watch on-demand on CAMECA’s website:

SIMS E-Book

Take a more detailed look at SIMS in this e-book co-edited by Wiley:

- Advantages of dynamic SIMS compared to other surface analysis techniques

- Components of a dynamic SIMS instrument

- How and where it can be used

- Case studies illustrating how SIMS is used in life science, materials science and cosmochemistry

- The future of dynamic SIMS, including advances in detection sensitivity and spatial resolution for new applications

The e-book is available to download from CAMECA’s website:

CAMECA SIMS Range

Blue Scientific is the official distributor for CAMECA in the UK, Ireland and Finland. We offer their entire range of SIMS systems, all of which feature dynamic SIMS:

- IMS 7f-Auto

Fully automated - IMS 7f-GEO

For geology - IMS 1300-HR³

Large geometry SIMS for geoscience - KLEORA

For geochronology

- NanoSIMS 50L

Ultra-fine feature analysis - IMS Wf & SC Ultra

For semiconductors - SIMS 4550

For semiconductors - Shielded IMS

For radioactive samples

More Information

If you have any questions, or if you’d like a quote, just get in touch: