Failure Analysis with Integrated SEM-EDS

SEM and EDS are commonly used techniques in failure analysis. By integrating both techniques in one system, the new Thermo Scientific Axia ChemiSEM makes it much quicker and easier to identify the root cause of failures. It’s up to twice as fast as conventional workflows, for a lower cost-per-sample and long-term savings.

Blue Scientific is the official distributor for Thermo Scientific entry-level SEM in the UK and Ireland. For more information or quotes, please get in touch.

More articles about failure analysis

Thermo Scientific SEM range

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

SEM and EDS in Failure Analysis

A key part of failure analysis is identifying the root cause of failures. Usually a combination of SEM (Scanning Electron Microscopy) and EDS (Energy Dispersive X-ray Spectroscopy) is used to examine the structure and elemental composition of a failed device, to identify the defect that caused the breakdown. Researchers collect dimensional information, electrical measurements and material characteristics.

Making SEM-EDS Easier

SEM-EDS is typically a complex procedure that requires two separate systems with different hardware, PCs and software interfaces. The workflow can be laborious and requires a lot of training.

However, the new Thermo Scientific Axia ChemiSEM simplifies the process enormously by integrating SEM and EDS into a single platform. There’s no need to switch between two systems – it’s completely combined.

Always-On EDS

EDS analysis is always on, providing instant access to quantitative elemental information directly from within the SEM image. EDS information can be viewed at any time it’s needed. You can switch specific elements on and off, and isolate areas for further examination.

- Acquire actionable data up to twice as fast as conventional SEM-EDS.

- Easy to use, with automated features eg alignment.

- Minimal training required.

- Fits large samples eg tubular heating elements.

Determine the Root Cause

The Axia ChemiSEM makes it much quicker and easier to acquire information about structure and elemental composition at the micro level, to pinpoint the cause of failures in a range of materials and devices. It provides data significantly faster than conventional SEM-EDS analysis, making the cost-per-sample much lower, for long-term savings.

Case Studies

Take a look at these examples of failure analysis in specific industries:

- Failure Analysis of Metals

- Glass Fibre-Reinforced Polymers and Composite Materials

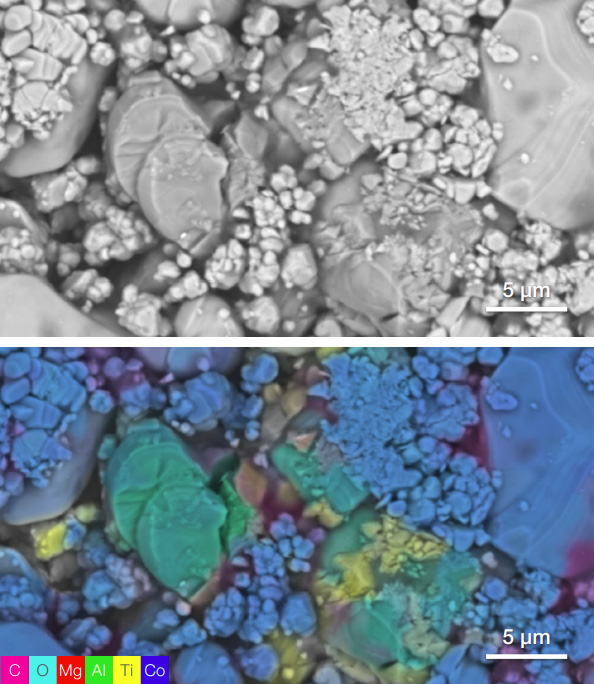

- Battery Material Contaminants

Example: Tubular Heating Element

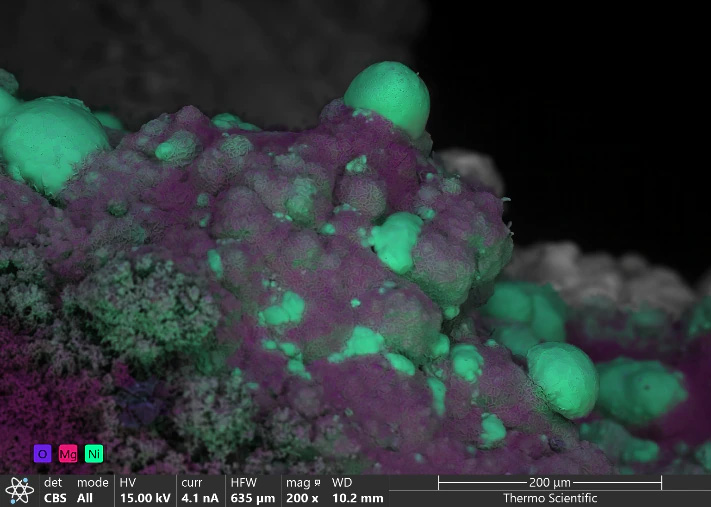

This example involves a heating element from a kitchen stove. These types of tubular heating elements (aka Calrod type heaters) are found in many common household appliances eg dishwashers, water heaters, heating blankets, toasters and hairdryers. Failure could cause fire, property damage and even loss of life, so it’s important to ensure that they’re safe.

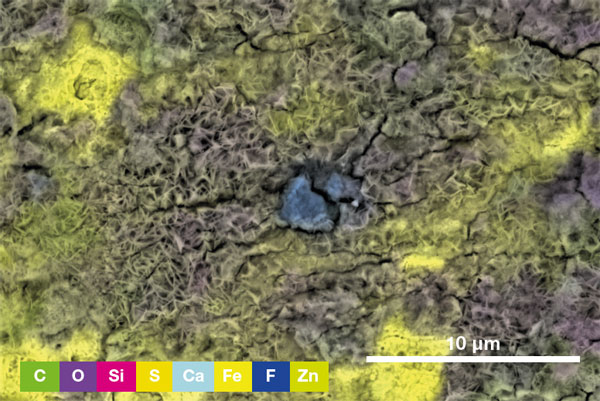

SEM and EDS can be used to determine the composition of the coiled heating element wire, insulator and sheath. In particular it can be used to check for evidence of shorting in the coiled heating element. It’s possible that the protective sheath can cause high temperature arcing, becoming an ignition source for fire.

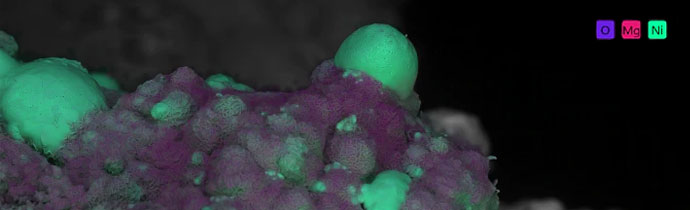

The SEM-EDS image below shows re-melted beads of nichrome, which indicates extreme overheating of the tubular heating element. This image was taken using the Thermo Scientific Axia ChemiSEM.

Colour SEM images are easy to interpret, making it quick to spot anomalies, contamination and defects. More about Colour SEM…

Thermo Scientific Axia ChemiSEM

- SEM with live EDS quantitative elemental mapping.

- Easy to use, with automated features.

- View quantitative elemental information at any time.

- Large, flexible chamber.

- Acquire data twice as fast as conventional SEM-EDS.

Demos and Workshops at MMC 2021

Join us at MMC 2021 microscopy conference (online) on 5-9th July 2021 to find out more about the Axia ChemiSEM and entry-level SEM from Thermo Scientific.

Workshops

- Wednesday 7th July 2021, 12:15 – 12:45pm

Using SEM/EDS for rapid and accurate failure analysis (run by BlueScientific) - Wednesday 7th July 2021, 1:45 – 2:15pm

ChemiSEM – Real-time problem solving for SEM-EDS (run by Thermo Scientific)

Book your place at the workshops when you register for MMC 2021. It’s free to attend the exhibition – and this also includes the workshops! If you’re already registered, you can add the workshops to your schedule on the MMC website.

Live Demos

Thermo Scientific will be running live, online demos at MMC 2021 on 7th, 8th and 9th July. See these systems in action:

Book a one-to-one

Dr. Stefan Schwarzmueller, product specialist in industrial electron microscopy at Thermo Scientific will be available for one-to-one online meetings throughout MMC 2021 (5-9th July 2021). Book a slot here:

More Information

Blue Scientific is the official distributor of Thermo Scientific entry-level SEM in the UK and Ireland. The range includes both floor-standing and desktop instruments. We’re available to advise on which system would be best for your research, arrange demos and provide quotes – just get in touch: