High Temperature In-Situ Mechanical Testing

High temperature in-situ mechanical testing, using a Hysitron PI series SEM PicoIndenter. A study of indentation on silicon at extreme temperatures.

Contact us

View our scientific instruments

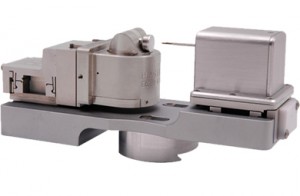

SEM PicoIndenter

The Hysitron PI Series SEM PicoIndenter is a depth-sensing mechanical test system designed to interface with a wide range of scanning electron microscopes (SEM). They uniquely couple the ability to acquire quantitative nano-mechanical data with the power to control the test position precisely. The sample can be observed before, during and after each test for a complete understanding of the deformation and failure processes.

The Hysitron PI Series SEM PicoIndenter is a depth-sensing mechanical test system designed to interface with a wide range of scanning electron microscopes (SEM). They uniquely couple the ability to acquire quantitative nano-mechanical data with the power to control the test position precisely. The sample can be observed before, during and after each test for a complete understanding of the deformation and failure processes.

Extended Range PicoIndenter

The PI 87xR SEM PicoIndenter offers an enhanced load and displacement range, combined with the ability to tilt and rotate the sample for superior tip-sample alignment, or align with additional detectors for supplemental analysis without breaking the vacuum.

800°C In-Situ Heating

Equipping the PI 87xR with the 800°C heating option adds the ability to conduct nano- and micro- mechanical tests on advanced materials in conditions that mirror their extreme operating environments, while directly observing the tests with SEM imaging. The 800°C heating module is designed for active heating of both the tip and sample for test stability, while minimising thermal flow to other parts of the instrument.

Indentation on (001) Si

The influence of temperature on mechanical stability has long been an area of interest across the materials spectrum. Silicon, for example, exhibits a remarkable resistance to softening at moderate temperatures (<500°C), with only a small reduction in measured hardness. The objective of this study is to understand the mechanical properties and softening effect of Si at much higher temperatures.

To evaluate the effect of temperature, a PI 87xR equipped with a cube-corner indentation probe was used to perform a series of quasi-static indentation tests on (001) Si at room temperature, 400°C & 800°C.

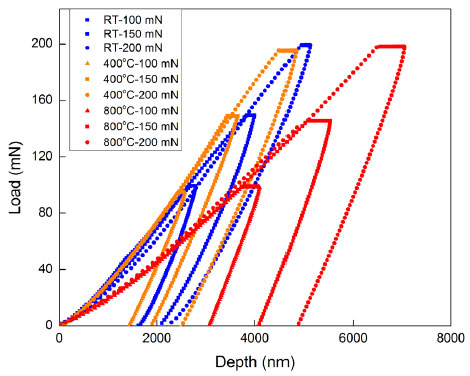

Load-displacement plots from the indentation tests performed

at room temperature, 400°C, and 800°C.

Load-Displacement Plots

The force versus displacement curves from the indentation testing at each of the temperatures are above. The data collected at 400°C shows a repeatable increase in the hardness of the (001) Silicon at this temperature relative to room temperature, possibly caused by the suppression of observable fracture at 400°C, as shown in the SEM images of the residual indent impressions below. The data from identical tests performed at 800°C indicates significant softening of the (001) Silicon, as the curves at this temperature achieve a much greater displacement relative to those collected at room temperature and 400°C.

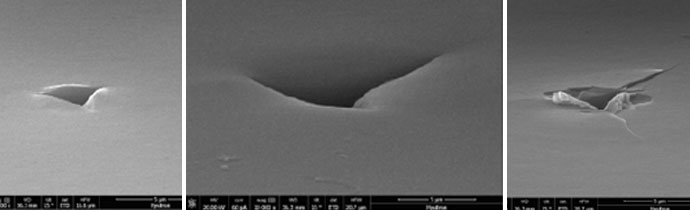

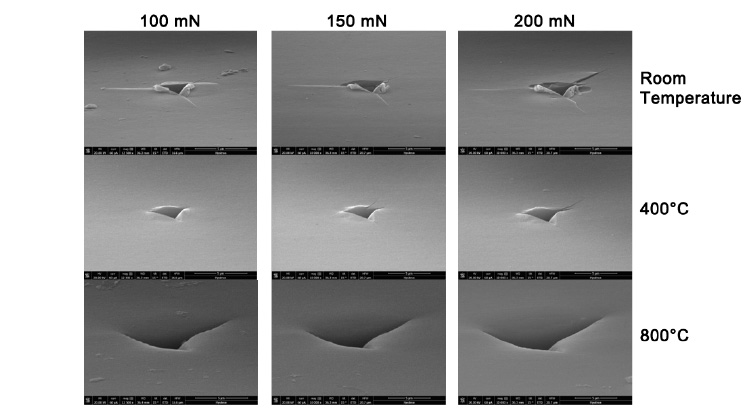

SEM images of the residual impressions resulting from the indentation tests.

Effect of Temperature: Brittle to Ductile Transition

- At room temperature, large radial cracks can be seen emanating from the corners of the impression in addition to significant spallation along the edges.

- At 400°C, the fracture resulting from indentation appears to be suppressed, indicating an increase in fracture toughness. This increase in toughness, in turn, results in an increase in hardness at 400°C

- The large, crack-free impressions at 800°C indicate significant softening and the transition to primarily ductile behaviour.

Other Applications of the SEM PicoIndenter and 800°C Heating Module

High temperature in-situ mechanical testing can also be used for:

- Automotive engine and exhaust components

- Thermal barrier coatings

- Nuclear materials

- High temperature fuel cells

- Metals and alloys

- Ceramics and ceramic-matrix components

Hysitron PicoIndenter Features

- Actively heated tip and sample for isothermal contact.

- Wide variety of tip materials and geometries.

- Mechanically secured sample for simplified test set-up.

- Low power, localised heating.

- Integrated thermal management system through active cooling.

- Multiple thermocouple attachment options for accurate temperature readings.

- Vacuum environment minimises reactive chemistries and oxidation of sensitive samples.

- Optional tilt and rotation capabilities for precise sample positioning, to ensure correct tip/sample alignment.

If you have any questions, or to discuss with our scientists whether high temperature in-situ mechanical testing would be suitable for your research, contact us on 01223 422 269 or info@blue-scientific.com