New Nano-Scratch Option for Bruker NanoForce Nanomechanical Testing System

New Nano-Scratch Option for the Bruker NanoForce

A new nano-scratch upgrade for the Bruker NanoForce makes it capable of nanoscale scratch testing and nanoindentation. The NanoForce is a nanomechanical testing system, which until now has been used for testing modulus and hardness of thin films and coatings.

Blue Scientific is the official distributor of the Bruker NanoForce in the UK and Nordic region (Switzerland, Iceland, Norway, Denmark and Finland). For more information or quotes please get in touch:

Contact us on 01223 422 269 or info@blue-scientific.com

Bruker NanoForce

All nano surface analysis instruments

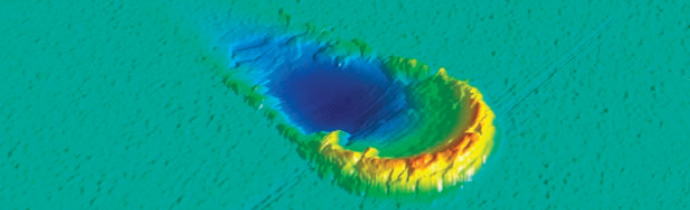

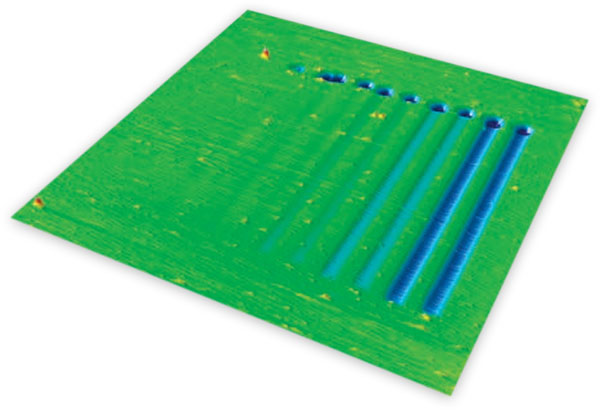

Constant load scratch tests (1, 3, 5, 7, 10 mN); length 20 μm; strain rate 0.1 Hz on 300 nm SiO2 on Si.

New Nanoscale Scratch Testing Option

The new nano-scratch option controls lateral displacement between tip and sample during nanoindentation. This significantly expands the capabilities of the NanoForce.

You can now characterise the resistance of thin films and coatings to:

- Scratching

- Cracking

- Chipping

- Scuffing

- Delamination

With instrumented indentation test, you can study the uniformity of mechanical properties on nanoscale surfaces and structures over large sample areas. All this, with the industry-leading low-noise floor, precision and stability of the NanoForce platform.

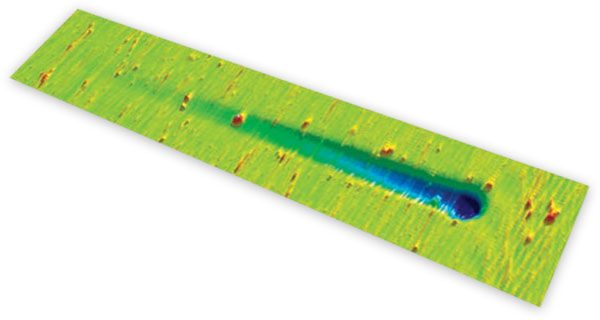

Progressive load scratch; length 20 μm, 1-10 mN; strain rate 0.1 Hz on 300 nm SiO2 on Si.

Bruker NanoForce nanomechanical testing system

About NanoForce

The Bruker NanoForce is a highly sensitive nanomechanical testing system with industry-leading measurement speeds. The measurement and control software is powerful and user friendly. Control experiments in real time, using recorded or calculated data.

The NanoForce uses highly accurate electromagnetic actuation technology. The instrument is based on Bruker’s established Dimension Icon® AFM technology. An innovative gantry design and hardware structure ensure highly accurate positioning and effective acoustic and vibration isolation. This provides the optimal testing environment for challenging nanoindentation applications in materials science. Wafer samples can be mounted with an optional 200 mm vacuum chuck. Additional built-in safety features protect the head assembly during X-Y stage translation.

[hr]